Onsite wastewater recycling for a global electronics manufacturer

Background

As part of their global sustainability roadmap, a global electronics manufacturer located in Singapore was looking for ways to reduce their impact on the environment through onsite wastewater recycling. This is their first office in the Asia Pacific region looking to implement this.

Sembcorp’s team of dedicated professionals worked with our customer throughout the entire project life cycle to design a bespoke wastewater recycling plant that will help to reduce total water usage by 17% and set a template for their other manufacturing sites to follow.

Challenges

- Complex wastewater stream

The wastewater from this manufacturing plant is particularly complex with significant and fluctuating pollutant loading. As such, there were a number of technical and O&M uncertainties to resolve.

- Space limitations

The wastewater from this manufacturing plant is particularly complex with significant and fluctuating pollutant loading. As such, there were a number of technical and O&M uncertainties to resolve.

- Pressure to demonstrate economic viability

Space was limited requiring our solution to be compact, space-efficient yet technologically advanced to treat their complex wastewater feed.

Solutions

With our years of experience in wastewater treatment, we came up with a cost-effective Ultrafiltration (UF) and Reverse Osmosis (RO) system and worked with our industrial partner to manufacture an innovative UF membrane that can withstand the harsh wastewater quality. The UF membrane enables greater durability and fouling resistance when compared to other commercially available membranes. This translates to minimal system downtime that usually occurs due to frequent backwashing or cleaning.

To tackle space constraints, we leveraged our process and engineering expertise to design a compact plant that was much smaller compared to those offered by other solution providers.

These solutions reduced their operating costs while enabling them to achieve their sustainability goals.

Results

Since its operations began in 2Q2022, the customer is able to save an average of 67,000m3 of NEWater per year, a reduction of 17% in total water usage. As our plant is digitally backed with WaterOS, our intelligent operations management system, we are able to assure our customer of the plant’s efficiency and reliability.

The customer also plans to implement similar water recycling projects across all their other factories in Singapore and Asia Pacific.

Long-term wastewater treatment services for a greenfield plant

Providing solutions to meet regulations

Background

A global pharmaceutical company venturing to set up their first manufacturing plant in Singapore faces multiple challenges due to varying wastewater characteristics and divergent regulations with existing countries of operations. Long-term plans are required to reduce operations and maintenance risks.

Sembcorp’s team of dedicated professionals, together with support from our overseas laboratory, is working with our customer to confirm the design for a bespoke wastewater treatment plant that when completed, will ensure treatability of expected wastewater effluent to meet discharge regulations. As a partner, Sembcorp will also review the wastewater characteristics consistently to ensure cost of wastewater treatment plant is optimised.

Challenges

- Complex wastewater streams with fluctuating quality

The wastewater from this new manufacturing plant is significantly complex due to the business nature. The wastewater is forecasted to vary due to changing product lines. An adaptable and efficient solution is required to ensure that regulations are met without impeding production schedule.

- Unaccustomed with local regulations

The discharge regulations in Singapore are different from customer's existing countries of operations and current wastewater treatment facilities cannot be fully replicated

Solutions

With our years of experience in wastewater treatment both in Singapore and overseas, Sembcorp provided in-depth consulting on the different discharge regulations and foreseeable hurdles that customer would face. Sembcorp proposed an intensive treatability studies to ensure system and wastewater quality consistency. To reduce customer risks, Sembcorp also proposed handling the operations and maintenance of the wastewater treatment plant upon completion to ensure compliance with local regulations on trade effluent discharge.

Wastewater treatment plant digitalisation and upgrading for a global pharmaceutical manufacturer

OPEX reduction through advance technology implementation

Background

Ever-rising costs of wastewater disposal compelled this global pharmaceutical giant to explore alternative ways to treat their wastewater. The customer also needs to ensure business continuity with O&M expertise to operate their wastewater treatment plant.

Sembcorp’s team of dedicated professionals, together with support from our overseas laboratory, is working with our customer to confirm the design for a bespoke wastewater treatment plant that when completed, will ensure treatability of expected wastewater effluent to meet discharge regulations. As a partner, Sembcorp will also review the wastewater characteristics consistently to ensure cost of wastewater treatment plant is optimised.

Challenges

- Difficult to treat wastewater stream

The harsh wastewater is high in TDS and COD in great excess, surpassing PUB Trade Effluent Discharge Limits. Conventional physical and biological processes cannot be used to treat this wastewater stream, so it is sent for off-site incineration.

- Brownfield limitations

As the plant manufacturing processes cannot be stopped, all modifications and system implementations are required to be performed with minimal shutdown period

- Operations of wastewater treatment plant

Customer is not specialised in wastewater treatment and has difficulty hiring the right people for the job.

Solutions

Sembcorp proposed deploying its proprietary AOP system to treat the harsh wastewater. To ensure the success of this project, Sembcorp performed an intensive treatability studies plan to ensure that the new system is able to continuously and consistently treat this wastewater stream.

Addressing the challenges of operations, Sembcorp proposed implementing a digital platform – WaterOS, supported with onsite manpower to ensure 24/7 operations and monitoring for compliance – to allow customer to focus on their production.

These solutions, when implemented, are expected to reduce their overall disposal costs by ≥10% while enabling them to achieve their sustainability goals.

One of Asia’s top providers of food solutions and logistics services

This customer wants to minimise the quantity of the company’s wastewater discharge and recycle the treated wastewater for non-potable use within its facilities by 2030.

Our collaboration for this multi-year project began with a deep dive by our team of professionals to understand the company’s aspirations, business goals and challenges.

The challenges faced by our customer include:

- Achieving the company’s sustainability goal of minimising the quantity of wastewater discharge by 2030 according to the following metrics:

- Treating 100% of its wastewater

- Recycling 50% of the treated wastewater for non-potable use within its facilities

- Meeting stringent water regulatory requirements and compliance while achieving sustainability goal

- Lowering operational costs for the existing facilities

Data-driven solutions powered by Sembcorp’s in-house capabilities, in-process design and R&D

We conducted a comprehensive water treatability study to provide us with a data-based framework to develop the right solution to address the customer’s needs.

The outcome is a Build-Own-Operate / Build-Own-Operate-Transfer (BOO/BOOT) model that meets stringent regulatory requirements and minimises the volume of wastewater discharge. The proposed technology system includes the integration of physical, chemical and biological treatment processes such as Dissolved Air Floatation (DAF), Membrane Bioreactor (MBR), Anaerobic Reactor and Reverse Osmosis (RO) systems together with its energy recovery units.

The project is currently ongoing.

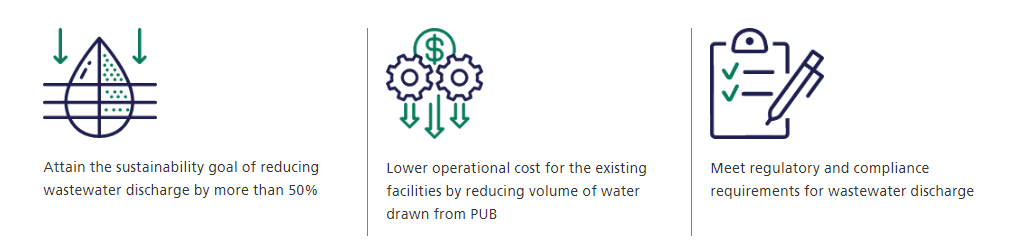

Targeted results

One of Asia’s largest healthcare companies that produces high-quality medical devices and pharmaceutical products

This company wants to achieve their sustainability goals of improving water efficiency though our integrated sustainability solutions. It requires that any solutions must continue to meet the highest standards in hygiene factors that are demanded by regulators, the industry, and its own internal expectations.

Our work for this multi-year project began with a deep dive by our team of professionals to understand the company’s business goals and business requirements.

The challenges faced by our customer include:

- Meeting stringent water regulatory and compliance requirements

- Achieving their sustainability goal of improving water efficiency by reducing water intake

- Minimising the quantity of wastewater discharge

Science-based solutions powered by Sembcorp’s in-house capabilities, in-process design and R&D

To conserve water supplies and achieve water efficiency, we developed an alternative water sourcing method by providing a closed-loop management system that reduces liquid discharge to zero (ZLD).

To minimise the quantity of wastewater discharge, we leveraged on a water treatability study combined with the collective expertise of our experienced Technology and Innovation Team to design an optimal Build-Own-Operate / Build-Own-Operate-Transfer (BOO/BOOT) package for a new on-site wastewater and water recovery plant.

The proposed technology system includes Dissolved Air Floatation (DAF), Membrane Bioreactor (MBR), Ultrafiltration (UF) and& Reverse Osmosis (RO) systems, Sludge dewatering system and dryersystem.Bioreactor (MBR), Anaerobic Reactor and Reverse Osmosis (RO) systems together with its energy recovery units.

The project is currently ongoing.

Targeted Results:

- Meet stringent water regulatory and compliance requirements with a wastewater recycling system for firewater and cooling tower make-up water

- Minimise water usage from PUB

- Recycle 500 m3/day of wastewater

A global semiconductor manufacturer in Singapore

As one of the largest semiconductor manufacturers headquartered in Singapore, the company requires large quantities of water with a very high level of purity for its manufacturing processes. Mindful of implications on water sustainability due to its business, the company wants to develop and implement a 5-year water conservation programme to tackle the challenges of water scarcity. However, it needed to first establish a baseline of its wastewater management systems from which it can evaluate potential technologies and strategies to meet its water recycling objectives.

Our team of water professionals worked with the customer to perform an audit of its current wastewater management system and produced a comprehensive report with recommendations to increase their wastewater recycling volume.

The challenges faced by our customer include:

- Legacy of Multiple Wastewater Management Systems

- Over the company’s decades-long operations, multiple fabs have been built to cater for the its expansion with different wastewater treatment technologies being deployed to meet the requirements at the time. This has resulted in multiple wastewater streams with large variances in flow and reclamation complexity.

- Space Scarcity leading to engineering challenges

- Space was limited due to the different wastewater treatment technologies that have been implemented over the years.

Science-based, data-driven solutions powered by Sembcorp’s in-house capabilities and R&D

By comprehensively mapping out the different wastewater management systems, we identified the various sampling points and their corresponding treatment specifications. This enabled us to plot and coordinate the site survey for sample collection.

The samples were sent to our Sembcorp Technology & Innovation Centre Lab for analysis. Based on our lab reports, we identified the optimal technology for our customer. We proposed a holistic proposal that met all of the customer’s parameters: the volume of water to be recycled, payback time calculation and space optimisation.

Results

- Provided a comprehensive process map of existing water resource management system

- Identified existing water operations and reclamation bottlenecks

- Sourced for novel technologies for specific treatment

- Jointly developed combination and segregation strategies for existing wastewater for optimal reclamation

- Met the high standards of water quality as required by its business